Welding systems are crucial in many industries, from manufacturing to construction. These systems include components like welding machines, torches, and consumables. Over time, these parts can deteriorate. Aging equipment can lead to reduced performance, increased maintenance costs, and potential safety risks. This article provides essential tips and strategies to combat aging in welding systems, ensuring longevity, efficiency, and safety.

I. What's Welding System Aging?

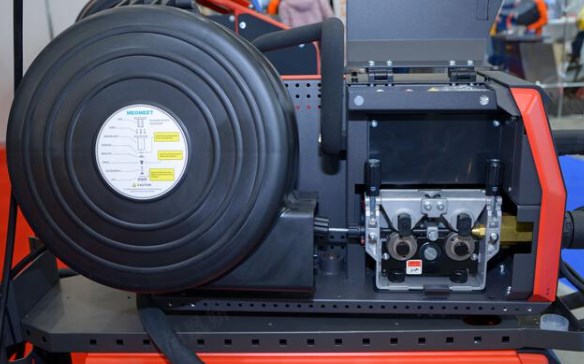

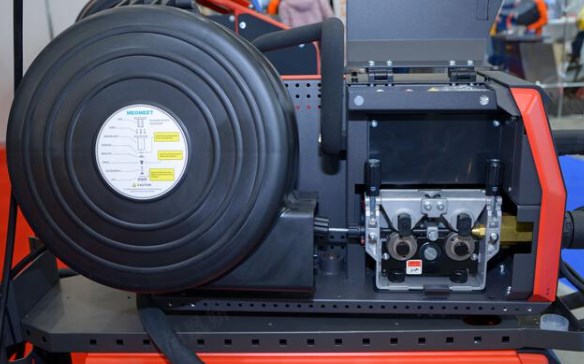

Welding systems are complex. They include machinery and parts that work under intense conditions. Each part has a lifespan influenced by usage, environment, and maintenance. For example, welding machines can last several years. Consumables like electrodes need frequent replacement due to wear and tear.

II. Signs of Aging in Welding Systems

Recognizing the signs of aging is crucial. Common symptoms include:

Reduced welding quality

Erratic operation

Unusual noises

Leaks

Visible wear like rust or corrosion

Ignoring these signs can lead to equipment failure, costly repairs, and compromised safety. Regular inspections and diagnostics are essential.

III. Preventive Maintenance Techniques

Preventive maintenance extends the lifespan of welding systems. Establish a regular maintenance schedule to detect and address issues early. Key tasks include:

Cleaning components to remove debris and contaminants

Lubricating moving parts to reduce friction

Calibrating equipment for accuracy

Implement predictive maintenance techniques like vibration analysis and thermal imaging to identify potential failures before they escalate.

IV. Extending Lifespan through Proper Usage

Proper usage practices impact equipment longevity. Operators should receive comprehensive training. This includes:

Understanding optimal settings for different welding processes

Maintaining a steady workflow to prevent overheating

Adhering to recommended duty cycles

Regularly inspect consumables and replace them as needed to ensure consistent performance and reduce strain on the system.

V. Environmental Considerations

Environmental conditions affect welding system aging. High humidity, extreme temperatures, dust, and corrosive chemicals can hasten deterioration. Protective measures include:

Storing equipment in climate-controlled environments

Using covers during downtime

Regular inspections can detect and address potential environmental damage early, prolonging equipment lifespan.

VI. Upgrading and Retrofitting Options

Sometimes, upgrading or retrofitting is more cost-effective than repairing aging equipment. Modern welding technology offers enhanced efficiency, reliability, and safety features. Upgrading to newer models or retrofitting existing equipment with advanced components can improve performance and extend lifespan.

VII. Troubleshooting Common Issues

Dealing with aging equipment involves identifying and addressing common issues to extend its lifespan and ensure it operates efficiently. Here are some common problems and their potential solutions:

1. Wear and Tear

Issue: Components deteriorate due to regular use.

Solutions:

Regularly inspect and replace worn-out parts.

Implement a preventive maintenance schedule.

Use high-quality replacement parts.

2. Obsolescence

Issue: Equipment becomes outdated and incompatible with newer systems.

Solutions:

Retrofit older equipment with modern components.

Upgrade software and firmware where possible.

Consider gradual replacement with newer models.

3. Decreased Efficiency

Issue: Aging equipment may operate less efficiently, consuming more power or taking longer to perform tasks.

Solutions:

Perform routine maintenance and calibration.

Clean internal and external parts to remove dust and debris.

Lubricate moving parts to reduce friction.

4. Frequent Breakdowns

Issue: Older equipment tends to break down more often, leading to increased downtime.

Solutions:

Keep a log of breakdowns to identify patterns and problematic components.

Maintain a stock of critical spare parts.

Train staff on quick fixes and troubleshooting techniques.

5. Difficulty Finding Replacement Parts

Issue: As equipment ages, finding parts can become challenging.

Solutions:

Develop relationships with multiple suppliers.

Consider using third-party or refurbished parts.

Look into custom manufacturing for critical components.

6. Outdated Safety Features

Issue: Older equipment may lack modern safety features, posing risks to operators.

Solutions:

Retrofit equipment with new safety features like guards, sensors, and emergency stops.

Conduct regular safety audits.

Provide thorough training on safe operation practices.

7. Data Inaccuracy

Issue: Aging equipment might produce inaccurate data or measurements.

Solutions:

Regularly calibrate measurement instruments.

Cross-check data with newer equipment.

Replace or repair faulty sensors and components.

8. Higher Operating Costs

Issue: Increased maintenance, energy consumption, and downtime lead to higher operating costs.

Solutions:

Conduct a cost-benefit analysis to determine when it's more economical to replace rather than repair.

Optimize usage to minimize energy consumption.

Implement energy-efficient upgrades where possible.

9. Software and Firmware Issues

Issue: Outdated software and firmware can lead to compatibility and security issues.

Solutions:

Regularly update software and firmware.

Replace equipment that can no longer be updated.

Use virtual machines or emulators to maintain compatibility.

10. Corrosion and Environmental Damage

Issue: Exposure to harsh environments can lead to corrosion and other damage.

Solutions:

Use protective coatings and covers.

Relocate equipment to less harsh environments if possible.

Regularly clean and inspect for signs of environmental damage.

General Tips for Managing Aging Equipment

Document Everything: Keep detailed records of maintenance, repairs, and performance issues.

Training: Ensure staff are trained to handle and maintain aging equipment.

Budgeting: Allocate funds for regular maintenance and eventual replacement.

Consult Experts: When in doubt, seek advice from manufacturers or industry experts on the best practices for maintaining aging equipment.

VIII. Conclusion

Proactive maintenance and strategic management are crucial to combating aging in welding systems. By understanding the factors that contribute to equipment deterioration, recognizing early warning signs, and implementing preventive measures, businesses can extend the lifespan of their welding systems. Embracing technological advancements and best practices not only enhances operational efficiency but also preserves valuable investments in welding equipment.

Related articles:

1. Tungsten Electrodes Basics: Types, Pros & Cons, Selection, Maintenance

2. 9 Maintenance Problems that Cause Bad Welds

3. What is the Importances Of Robotic Welding Systems In Industries?

4. How to Choose the Best Automated Welding System for your Application?

5. Fiber Laser Welding: Advantages, Systems and Applications