MIG welding is a popular and versatile technique that uses a wire electrode and a shielding gas to join metal parts. Whether you are a beginner or a professional, you can always improve your MIG welding skills by following these 11 tips.

Before you start welding, make sure you have the right equipment and settings for the job. You will need a MIG welder, a welding gun, a wire feeder, a shielding gas cylinder, a regulator, a hose, a ground clamp, and a welding helmet. You will also need to choose the right wire size, type, and polarity, as well as the appropriate gas flow and voltage for the metal you are welding.

2. Prepare the metal surface

To ensure a strong and clean weld, you need to prepare the metal surface by removing any dirt, rust, paint, oil, or grease. You can use a wire brush, a grinder, sandpaper, or a solvent to clean the metal. You should also make sure the metal is dry and free of moisture.

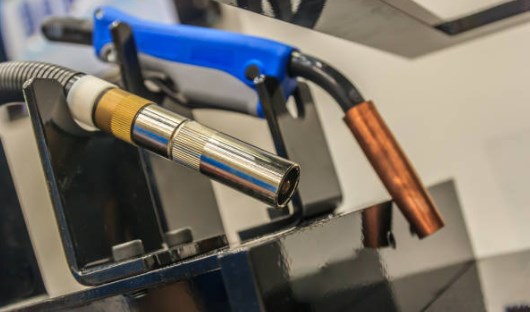

3. Position the torch correctly

The position of the torch is crucial for creating a good weld bead. You should hold the torch at a 10 to 15-degree angle from the vertical, and point it in the direction of travel. You should also keep the distance between the tip of the wire and the metal consistent, about 1/4 to 3/8 inch.

position the welding torch correctly

The travel speed and direction of the torch affect the shape, size, and penetration of the weld bead. You should move the torch at a steady and uniform speed, not too fast or too slow. You should also move the torch from left to right if you are right-handed, or from right to left if you are left-handed. This will help you avoid pushing or pulling the weld pool.

5. Use the right technique for the joint type

There are different types of joints that you can weld with MIG, such as butt, lap, T, corner, and edge. Each joint type requires a different technique and pattern to achieve a strong and neat weld. For example, for a butt joint, you can use a straight or a weave motion, while for a lap joint, you can use a U or a J motion.

6. Adjust the wire feed speed and voltage

The wire feed speed and voltage are two important parameters that affect the quality of the weld. The wire feed speed determines how fast the wire is fed into the weld pool, while the voltage determines how much heat is generated by the arc. You should adjust these settings according to the thickness and type of the metal, the position of the weld, and the desired penetration and bead width. A general rule of thumb is to increase the wire feed speed and voltage for thicker metals and decrease them for thinner metals.

The shielding gas protects the weld pool from atmospheric contamination that can cause porosity, spatter, and oxidation. The type and amount of shielding gas you use depend on the type and thickness of the metal, the position of the weld, and the desired appearance and quality of the weld. For example, for mild steel, you can use a mixture of argon and carbon dioxide, while for aluminum, you can use pure argon.

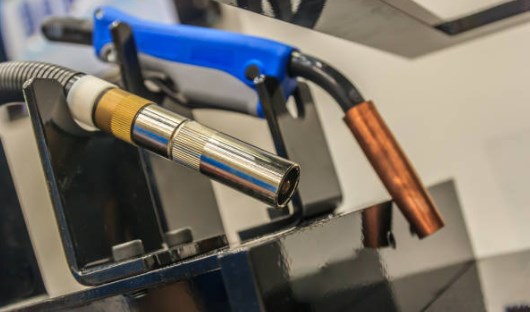

8. Maintain the equipment and consumables

To ensure optimal performance and safety, you should regularly maintain the equipment and consumables used for MIG welding. You should check the condition of the welding gun, the wire feeder, the gas cylinder, the regulator, the hose, the ground clamp, and the welding helmet. You should also replace the consumables, such as the contact tip, the nozzle, and the wire, when they are worn out or damaged.

9. Practice on scrap metal

One of the best ways to sharpen your MIG welding skills is to practice on scrap metal. This will help you improve your technique, speed, and accuracy, as well as test different settings and parameters. You can use scrap metal from old projects, or buy some from a local metal supplier.

10. Learn from the experts

Another way to sharpen your MIG welding skills is to learn from the experts. You can watch online videos, read blogs and articles, join forums and groups, or take courses and workshops. You can also ask for feedback and advice from other welders, or find a mentor who can guide you and teach you new tricks.

11. Keep learning and experimenting

The last tip to sharpen your MIG welding skills is to keep learning and experimenting. MIG welding is a dynamic and evolving field, with new technologies, materials, and methods constantly emerging. You should always be curious and open-minded, and try new things and challenges. You should also keep track of your progress and results, and celebrate your achievements.

Conclusion

MIG welding is a skill that can be improved with practice, knowledge, and the right tools. In this article, we have shared 11 tips to sharpen your MIG welding skills. By following these tips, you can create strong, clean, and neat welds for your projects. You can also enhance your efficiency, safety, and confidence as a welder.

Related articles

1. Spot Welding vs. TIG Welding vs. MIG Welding: Differences & How to Choose?

2. Shielding Gases for TIG & MIG Welding: which gas is best?

3. Pulsed MIG Welding: Mastering Techniques for Superior Results

4. Pulsed MIG Welding Aluminum and Stainless Steel

5. Pros and Cons of Stick Welding and MIG Welding