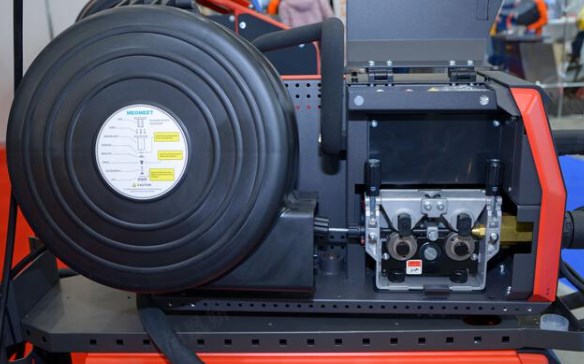

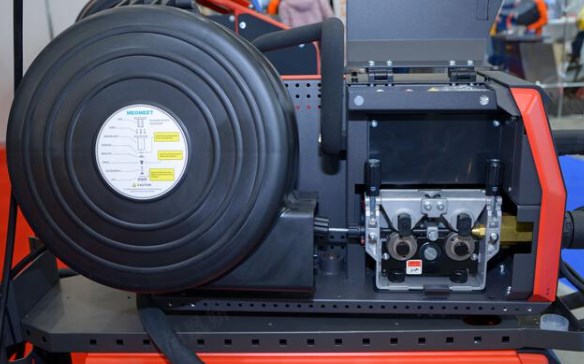

In the ever-evolving world of manufacturing and welding, having a reliable and efficient welding power supply is not just an option—it’s a necessity. Welding power supplies are the backbone of any welding operation, and their performance directly impacts the quality, efficiency, and cost-effectiveness of the final product. Among the many welding power supply brands available, Megmeet Welding Technology has emerged as a leader, earning the trust of welders and industries worldwide. But what makes the Megmeet welding power supply so popular? Let’s dive into the reasons and explore how Megmeet stands out in the competitive welding industry.

I. Unmatched Performance and Quality

When it comes to welding, precision and consistency are critical. Megmeet welding power supply is engineered with cutting-edge power electronics and advanced control technology to deliver stable and precise welding output. Whether you’re working with carbon steel, stainless steel, aluminum, or its alloys, Megmeet welding power supply adapts seamlessly to various materials. Additionally, it supports multiple welding modes, including:

CO₂/MAG/MIG/TIG/MMA Welding: Ideal for versatile applications in automotive, construction, and heavy equipment manufacturing.

Robotic Welding: Designed for high-precision automated welding processes in industrial settings.

Laser Welding: Perfect for advanced, high-speed welding applications requiring minimal heat input.

But what truly sets Megmeet apart is its ability to perform in extreme conditions. For instance, in the shipbuilding and marine engineering industries, where outdoor environments are often harsh (high temperatures, humidity, salt spray, vibrations, etc.), Megmeet welding machines have proven themselves to be reliable, stable, and efficient. Years of research and testing have equipped Megmeet welding power supply to handle these challenges with ease.

II. Tested for Reliability: HALT and Beyond

One of the standout features of the Megmeet welding power supply is its rigorous testing process. Megmeet employs HALT (Highly Accelerated Life Test) technology to simulate extreme environmental conditions and push the equipment to its limits. This process involves:

Overload the system to identify potential failures.

Increasing stress factors such as vibration, high temperatures, high humidity, salt spray, and more until the equipment fails.

Analyzing and optimizing the design to eliminate weaknesses.

Through HALT testing, Megmeet ensures that its welding power supply can withstand the toughest conditions and deliver a lifespan of at least 10 years—far exceeding industry standards. Other critical tests include:

Conducted Emission Testing: Ensuring the equipment doesn’t interfere with other devices and vice versa.

Surge and Lightning Testing: Protecting against voltage spikes and lightning strikes with a Class D (6000V/3000A) surge protection system.

Conductive Dust Testing: Verifying performance in environments with metallic dust and conductive pollutants.

High-Low Temperature Testing: Ensuring stability in extreme temperature fluctuations.

Salt Fog Testing: Evaluating corrosion resistance in high-humidity, high-salt environments.

Water Resistance Testing: Achieving an IP23S rating, ensuring operation even in heavy rain.

These tests guarantee that the Megmeet welding power supply can perform flawlessly in any environment, from the factory floor to outdoor construction sites.

III. Energy Efficiency and Cost-Effectiveness

In today’s competitive market, reducing operational costs is crucial. Megmeet welding power supply is designed with energy efficiency in mind, helping businesses save up to 30% on energy consumption compared to traditional welding power sources. By improving the power factor and optimizing energy usage, Megmeet welding power supply not only lowers your electricity bills but also reduces carbon emissions, aligning with global sustainability goals.

Moreover, the long lifespan and low maintenance requirements of the Megmeet welding power supply further reduce the total cost of ownership. With fewer repairs, longer equipment life, and reduced downtime, welders can focus on what matters most—producing high-quality results without breaking the bank.

IV. Smart, User-Friendly, and Adaptable

Modern welding demands more than just power—it requires intelligence and adaptability. Megmeet welding power supply is equipped with advanced digital features that make welding easier, faster, and more precise. Some of its intelligent features include:

Self-Adaptive Welding Parameters: Automatically adjusts welding settings based on material type and environmental conditions.

Real-Time Data Monitoring: Provides instant feedback on welding parameters, enabling welders to make adjustments on the fly.

User-Friendly Interface: An intuitive control panel allows even novice welders to operate the machine with ease.

Megmeet welding power supply is also highly adaptable. It can be integrated with various welding systems, including:

Welding Robots: Seamlessly connects with automated welding systems for high-precision industrial applications.

Industrial IoT (IIoT): Compatible with smart manufacturing systems for data-driven decision-making.

Whether you’re a small workshop or a large industrial facility, the Megmeet welding power supply can be customized to meet your specific needs.

V. Trusted by Industries Worldwide

Megmeet welding power supply is not just popular—it’s a trusted partner for industries across the globe. Its exceptional performance, reliability, and versatility have made it the preferred choice for:

Automotive Manufacturing: For bodywork, chassis, and component welding.

Construction and Steel Fabrication: For building frames, pipelines, and structural components.

Home Appliances: For manufacturing refrigerators, air conditioners, and other appliances.

Shipbuilding and Marine Engineering: For welding large-scale marine structures.

Heavy Equipment and Machinery: For manufacturing cranes, excavators, and other heavy machinery.

Megmeet’s reputation is backed by numerous awards and certifications, including the National Science and Technology Progress Award, China Quality Award, ISO 9001, CE, and UL certifications. These recognitions are a testament to the brand’s commitment to excellence and innovation.

VI. Backed by a Global Leader in Electrical Automation

Megmeet Welding Technology is a subsidiary of Megmeet Electric, a global leader in electrical automation solutions. Founded in 2003 and headquartered in Shenzhen, China, Megmeet Electric has grown into a powerhouse with:

7,500+ Employees dedicated to innovation and customer satisfaction.

1,600+ R&D Engineers driving cutting-edge technology development.

25.7 billion RMB in Registered Capital, ensuring robust infrastructure and resources.

6 Business Segments, including power supply products, industrial automation, new energy, smart equipment, and more.

With such a strong foundation, Megmeet Welding Technology is poised to continue leading the welding industry into the future.

Conclusion: Why Choose Megmeet Welding Power Supply?

If you’re looking for a welding power supply that combines high performance, energy efficiency, intelligent features, and unmatched reliability, look no further than Megmeet Welding Technology. Its cutting-edge welding solutions have already transformed the operations of industries worldwide, helping them achieve better results while saving time and money.

Whether you’re a professional welder, a small business owner, or the head of a large manufacturing facility, Megmeet welding power supply is the ultimate choice for your welding needs. Contact Megmeet Welding Technology Services Center today to learn more about how their products can elevate your welding operations to the next level.

FAQs:

Q1. What makes Megmeet welding power supply different from competitors?

Megmeet stands out due to its advanced testing processes (like HALT), energy efficiency, intelligent features, and compatibility with various welding systems.

Q2. What industries use the Megmeet welding power supply?

Megmeet welding power supply is widely used in automotive, construction, shipbuilding, heavy equipment manufacturing, and more.

Q3. Is Megmeet welding power supply suitable for outdoor use?

Yes, Megmeet welding power supply is designed to handle harsh outdoor conditions, including high humidity, salt spray, and extreme temperatures.

Q4. How long does the Megmeet welding power supply last?

Q5. Can the Megmeet welding power supply be customized?

By choosing Megmeet Welding Technology, you’re not just investing in a welding power supply—you’re investing in a future of efficiency, reliability, and innovation. Take the first step toward transforming your welding operations today!

Related articles

1. How to Select and Use an Arc Welding Power Source?

2. Revolutionize Your Welding Process with Megmeet Welding Power Sources

3. Congratulations! Market share of Megmeet Robotic Welding Power Source in China is Consecutively TOP-ONE, Recognized by GGII

4. Top Inverter Welding Machine Brands in the World & How to Choose

5. Improve Your Productivity With Easy-To-Use Welding Machines