Mig welding, also known as gas metal arc welding (GMAW), is a versatile and efficient welding process that uses a continuous wire electrode and a shielding gas to join metal pieces together. Mig welding can be performed in different modes of metal transfer, depending on the welding parameters and the desired outcome. Two of the most common modes are short arc and spray transfer, which have distinct characteristics and applications.

I. Mig Welding – Short Arc Transfer

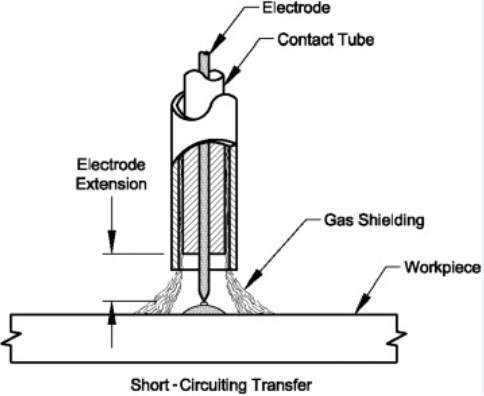

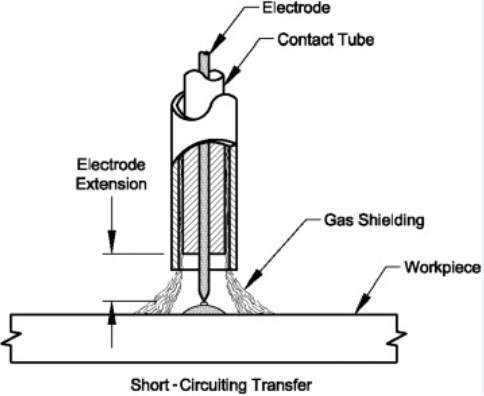

Short arc transfer, also known as short circuit transfer, is a low-energy mode that uses a relatively low welding current and voltage. In this mode, the wire electrode touches the molten weld pool periodically, creating a short circuit that causes the electrode to melt and detach small droplets of filler metal. These droplets are transferred to the weld pool at a high frequency, ranging from 20 to over 200 times per second. The short-circuiting also generates heat that sustains the arc and the welding process.

Short arc transfer produces a small, fast-freezing weld pool that is suitable for welding thin sections, out-of-position welding, and filling large root openings. It also minimizes distortion and spatter, as well as reduces the heat-affected zone and the risk of burn-through. However, short arc transfer has some limitations, such as low deposition rate, low penetration, and poor fusion. It also requires a careful adjustment of the wire feed speed and the inductance to achieve a stable and smooth metal transfer.

II. Mig Welding – Spray Transfer

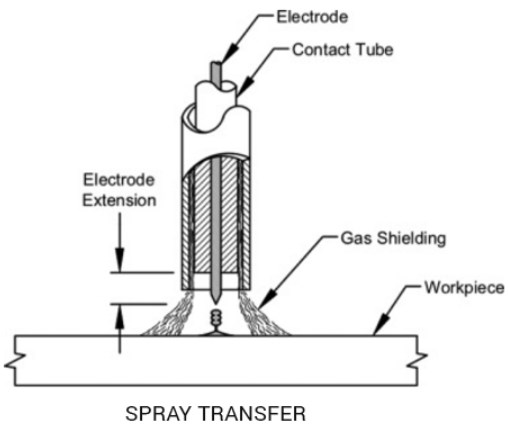

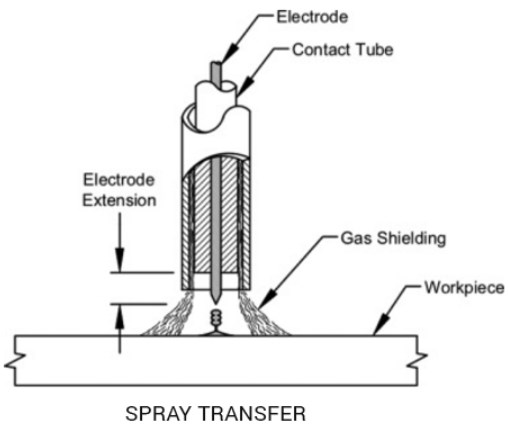

Spray transfer, on the other hand, is a high-energy mode that uses a relatively high welding current and voltage. In this mode, the wire electrode melts rapidly and forms small, fine droplets that are propelled across the arc gap by electromagnetic forces. The droplets are transferred in a spray-like pattern, similar to a fine spray of water from a hose nozzle. The high velocity of the droplets allows them to bridge the gap between the electrode and the workpiece, resulting in a stable and continuous arc.

Spray transfer produces a large, deep-penetrating weld pool that is suitable for welding medium and thick plates in flat or horizontal positions. It also offers a high deposition rate, high travel speed, good fusion, and excellent weld quality. However, spray transfer has some drawbacks, such as high heat input, high spatter, high fume generation, and high noise level. It also requires a proper shielding gas composition, such as argon or argon-carbon dioxide mixtures, to prevent oxidation and ensure a clean weld.

III. Comparison of Short Arc and Spray Transfer

| Mode | Current | Voltage | Droplet Size | Frequency | Weld Pool Size | Penetration | Deposition Rate | Spatter | Fume | Noise | Shielding Gas | Position | Application |

|---|

| Short arc transfer | Low | Low | Large | High (20-200 Hz) | Small, fast-freezing | Low | Low | Low | Low | Low | CO2 or CO2-rich mixtures | All positions | Thin sections, out-of-position welding, filling large root openings |

| Spray transfer | High | High | Small, fine | Low (1-10 Hz) | Large, deep-penetrating | High | High | High | High | High | Ar or Ar-rich mixtures | Flat or horizontal positions | Medium and thick plates |

In conclusion, MIG welding can be performed in different modes of metal transfer, depending on the welding parameters and the desired outcome. Short arc transfer is a low-energy mode that produces a small, fast-freezing weld pool that is suitable for welding thin sections, out-of-position welding, and filling large root openings. Spray transfer is a high-energy mode that produces a large, deep-penetrating weld pool that is suitable for welding medium and thick plates in flat or horizontal positions. Both modes have their advantages and disadvantages, and the welder should choose the appropriate mode based on the specific welding situation.

Related article:

1. Megmeet RDT (Retract Droplet Transfer) Cold Metal Transfer Zero-Spatter High-speed Servo Arc Welding Technology Makes Its Debut at the Exhibition

2. MIG Welding: The Basics for Mild Steel

3. Push or Pull Mig Welding: Which One to Choose?

4. The Ultimate Guide to MIG Short Circuit Welding Techniques

5. Guide to Pulsed MIG Welding in Manufacturing