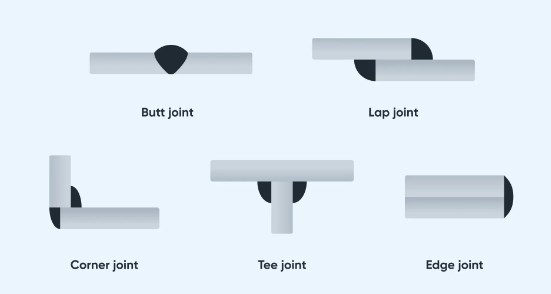

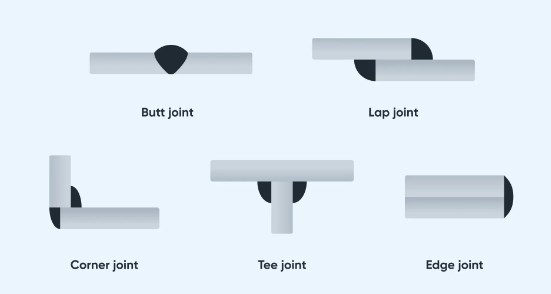

Welding is a process of joining two or more pieces of metal or plastic by applying heat, pressure, or both. Welding can be done using different methods, such as arc welding, gas welding, resistance welding, laser welding, etc. Depending on the shape and position of the pieces to be joined, different types of welding joints can be used. Here are some of the most common welding joint types and their characteristics:

I. Butt Joint

A butt joint is a type of welding joint where the edges of the pieces are aligned and joined together along a single plane. This is one of the simplest and most widely used welding joints. It can be used to join flat or curved surfaces, such as pipes, plates, tubes, etc. A butt joint can be classified into different types based on the preparation of the edges, such as square butt joint, single V butt joint, double V butt joint, etc.

II. Lap Joint

A lap joint is a type of welding joint where one piece overlaps another and they are joined together along the overlapping area. This is a stronger and more rigid joint than a butt joint, as it provides more surface area for welding. It can also be used to join dissimilar materials or different thicknesses of materials. A lap joint can be classified into different types based on the number and position of the welds, such as single lap joint, double lap joint, fillet lap joint, etc.

III. Tee Joint

A tee joint is a type of welding joint where two pieces are joined at right angles to form a T-shape. This is a common joint for structural applications, such as frames, beams, columns, etc. A tee joint can be classified into different types based on the shape and position of the welds, such as fillet tee joint, groove tee joint, plug tee joint, etc.

IV. Edge Joint

An edge joint is a type of welding joint where the edges of two parallel or nearly parallel pieces are joined together along a common plane. This is a less common and weaker joint than other types, as it provides less surface area for welding. It is mainly used for joining thin materials or for temporary purposes. An edge joint can be classified into different types based on the preparation of the edges, such as square edge joint, single V edge joint, double V edge joint, etc.

V. More Welding Joint Types

Many other types of welding joints can be used for specific purposes or applications. Some examples are:

Corner Joint: A type of welding joint where two pieces are joined at an angle to form an L-shape.

Cross Joint: A type of welding joint where two pieces cross each other at an angle and are joined at the intersection.

Flare-V Groove Joint: A type of welding joint where one piece has a flared edge and another piece has a V-shaped groove, and they are joined together along the groove.

Flare-Bevel Groove Joint: A type of welding joint where one piece has a flared edge and another piece has a beveled edge and they are joined together along the bevel.

J-Groove Joint: A type of welding joint where one piece has a J-shaped groove and another piece has a flat edge, and they are joined together along the groove.

Spot Weld: A type of welding joint where two pieces are joined together by applying pressure and heat to a small area using electrodes.

Seam Weld: A type of welding joint where two pieces are joined together by applying pressure and heat along a continuous line using electrodes.

In conclusion, welding is a versatile and useful process of joining different materials together. Many types of welding joints can be used depending on the shape, position, and purpose of the pieces to be joined. Some of the most common welding joint types are butt joint, lap joint, tee joint, and edge joint. Each type has its advantages and disadvantages and requires different preparation and techniques. By understanding the characteristics and applications of different welding joint types, one can choose the best option for their welding project. To learn more welding tips, view: https://www.megmeet-welding.com/en/news.

Related articles:

1. Welding Porosity: Causes, Types, Effects and Solutions

2. How to Weld Thin Metal: Types, Welders, and Techniques (2023)

3. Welding Gases: Different Types & Their Uses

4. 10 Welding Machine Types and Their Applications

5. A Comprehensive Guide to Different Types of Welding Procedures