In a significant recognition of its dominance in the industry, Megmeet Welding Technology, a trailblazer in China's heavy-duty industrial welding equipment sector, has once again emerged as the market leader. According to the latest data from Gaogong Industrial Research and Robotics Institute (GGII), a renowned authority in the robotics industry, Megmeet has retained its position as the No. 1 supplier of robotic power sources in China for the seventh consecutive year. This achievement underscores the company's relentless pursuit of innovation and unwavering commitment to delivering cutting-edge welding solutions.

The GGII report highlights that in 2020 and 2021, the Chinese market witnessed the sale of 34,100 and 41,600 welding robots, respectively. Megmeet's arc welding robotic power sources accounted for over 10,000 units, capturing nearly 30% of the market share. This impressive figure solidifies Megmeet's position as a leader in the robotic welding machines market, further cementing its reputation as a pioneer in the industry.

I. A Legacy of Innovation and Excellence

Megmeet's journey to the top is a testament to its dedication to technological innovation and customer-centric solutions. Over the years, the company has consistently invested more than 10% of its annual revenue into research and development (R&D), ensuring that it stays ahead of the curve in the rapidly evolving welding industry. With a team of over 1,500 professional R&D engineers, Megmeet has established state-of-the-art research and development centers in key locations, including Shenzhen, Xi'an, Wuhan, Changsha, Zhuzhou, Sweden, and Germany.

Megmeet's global footprint extends beyond R&D, with production and manufacturing centers strategically located in Zhuzhou, Taizhou, Zibo, Heyuan, Thailand, and India. This extensive network enables Megmeet to cater to the diverse needs of its clients worldwide, providing high-quality welding products that combine efficiency, reliability, energy savings, and intelligence.

II. Breaking Barriers with Cutting-Edge Technology

Megmeet's commitment to innovation is evident in its integration of multi-disciplinary technologies to redefine the standards of inverter intelligent welding machines. The company has pioneered several groundbreaking technologies, including:

"Droplet Necking Detection and Control": A revolutionary system that ensures precision welding by dynamically monitoring and adjusting the welding process in real time.

"Short Arc Pulse": A high-precision welding technique that minimizes spatter and ensures a smooth, consistent weld joint.

"Extremely Low Spatter Smooth Short Circuit Transition": An advanced welding mode that reduces spatter and ensures a seamless transition between short-circuit and spray welding processes.

These innovations, along with over 100 technical patents, have not only strengthened Megmeet's competitive edge but also earned widespread acclaim from customers across the globe.

III. Empowering Customers to Excel

At the heart of Megmeet's success is its customer-centric philosophy. The company is driven by a simple yet powerful mission: "Helping our customers outperform their competitors in welding production, ensuring they can focus on their core business and stand out in their respective industries."

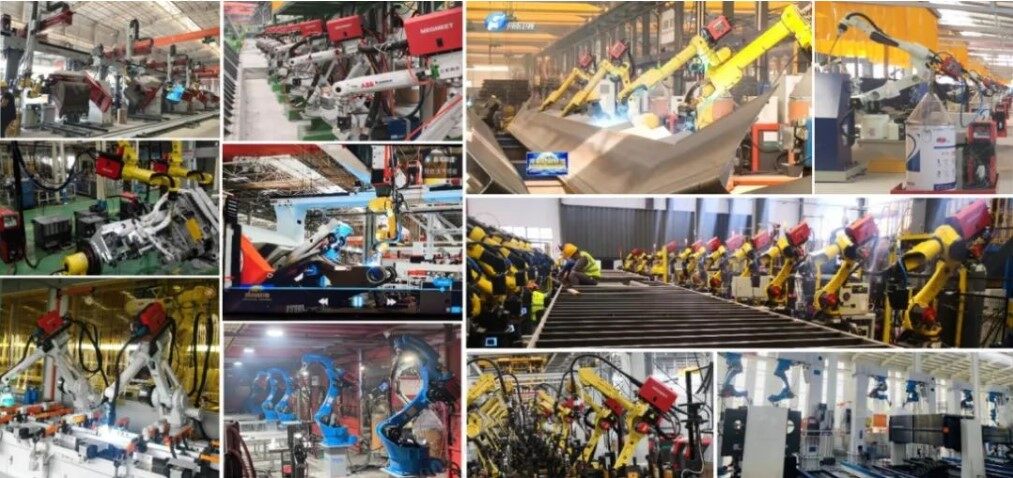

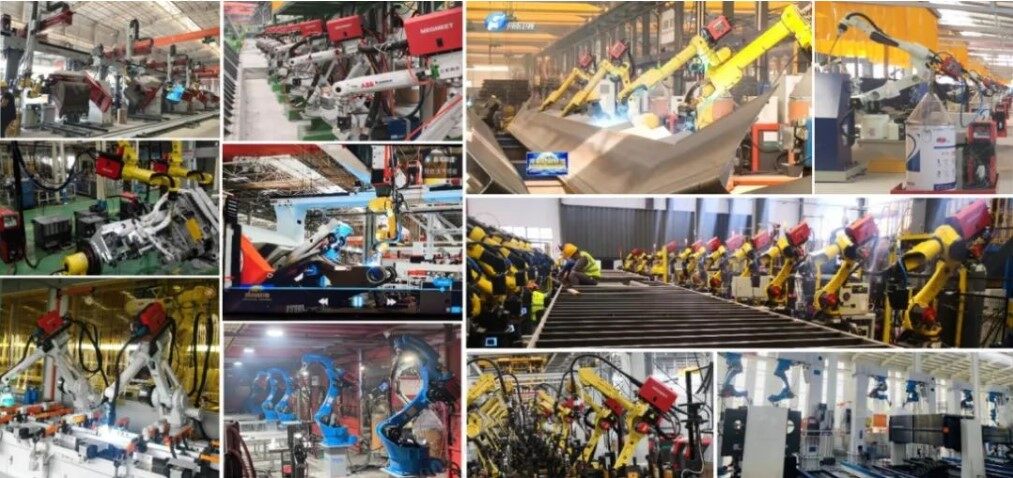

To achieve this, Megmeet offers a comprehensive portfolio of robotic welding solutions, including intelligent welding machines, welding automation systems, and customized welding technologies. These solutions are designed to address the unique challenges faced by manufacturers in industries such as automotive, aerospace, heavy machinery, and more.

By leveraging Megmeet's cutting-edge welding technologies, businesses can achieve:

Higher efficiency: Streamlined welding processes that reduce production time and costs.

Improved quality: Consistent weld quality that meets the most stringent industry standards.

Energy savings: Eco-friendly welding solutions that minimize power consumption.

Enhanced productivity: Automation and intelligence that enable manufacturers to focus on core operations.

A Vision for the Future

As Megmeet continues to lead the robotic welding machines market, the company remains committed to its vision of shaping the future of welding technology. With a focus on sustainability, innovation, and customer satisfaction, Megmeet is poised to expand its global influence and set new benchmarks for the industry.

For businesses seeking a trusted partner to elevate their welding operations, Megmeet stands as a beacon of excellence. With its unparalleled expertise, cutting-edge solutions, and unwavering commitment to innovation, Megmeet is not just a market leader—it's a driving force in the evolution of the welding industry.

Related articles:

1. Megmeet Welding: Reigning as "Gold Supplier" of LGIM, Achieving New Heights!

2. 2022 Industrial APP Digital Manufacturing & Management Reward

3. Megmeet was certified by AWS as the First CRAW Center in Asia

4. Megmeet 1,500 Robot Welding Power Sources Signing Ceremony!

5. Synergy of Megmeet Welding Technology with Robotic Precision