With the continuous advancement of industrial technology, welding technology is also developing rapidly. Modern welding equipment not only requires efficiency and precision but also emphasizes intelligence and environmental performance. In this context, the Megmeet Intelligent Welding Machine has quickly become the focus of the market due to its outstanding technological advantages. So, what are the unique performance characteristics of the latest welding machines? This article will take Megmeet Intelligent Welding Machine as an example to provide a detailed analysis of the innovative highlights of these welding machines, helping you find the most suitable solution in the world of welding technology.

I. Intelligent Operation - the Future of Welding Technology

1)Automated Programming Technology

The latest welding machines have taken an important step in intelligent operation, especially in the development of automated programming technology. Megmeet Intelligent Welding Machine embeds expert-level welding data through preset programs and intelligent algorithms, helping welders select welding parameters such as current, voltage, and welding speed, thus achieving high-quality welding results. Welders only need to set simple welding requirements, and the welding machine can automatically complete complex welding tasks. This technology not only greatly improves welding efficiency but also reduces errors caused by human operations.

2)Human-Machine Interaction Interface

The operation interface of the new welding machines such as Megmeet welders is more user-friendly, using high-definition touch screens and graphical interfaces, allowing welders to set and adjust parameters through simple touch operations. Some high-end welding machines are also equipped with voice control systems, further simplifying the operation process. This improvement in the human-machine interaction interface not only reduces the learning curve for welders but also improves the accuracy and efficiency of welding operations.

3)Remote Monitoring and Management

Megmeet Intelligent Welding Machine supports remote monitoring and management functions. Through an internet connection (such as Megmeet SMARC Intelligent Welding Informatization Cloud Platform), management personnel can monitor the working status of welding machines in real-time, and identify and solve potential problems in a timely manner. In addition, remote management functions also support fault diagnosis and software upgrades for welding machines, ensuring that the equipment is always in the best condition.

II. High-Efficiency Performance - Qualitative Leap in Welding Efficiency

1)High-Frequency Inverter Technology

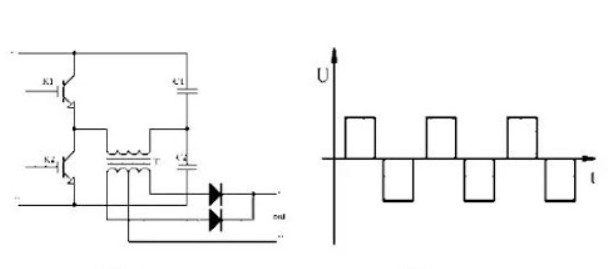

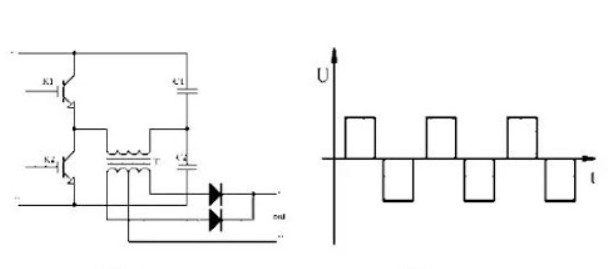

High-frequency inverter technology is a major highlight of the latest welding machines. Megmeet welding machines use high-frequency inverter technology, which, compared to traditional industrial frequency welding machines, have the advantages of small size, lightweight, and high efficiency. This technology significantly reduces the size and weight of transformers by increasing the current frequency, while also improving energy conversion efficiency, making the overall performance of the welding machine superior.

2)Digital Control Technology

The application of digital control technology has greatly improved the accuracy and stability of the latest welding machines. Megmeet's fully digital control intelligent welding machine can monitor and adjust welding parameters in real-time to ensure optimal welding results. This high-precision control capability enables welding machines to handle various complex welding environments with ease, meeting the requirements of various materials and processes.

3)High-Efficiency Welding Power Supply

The latest welding machines generally adopt high-efficiency welding power supplies. Megmeet welding machines are equipped with high-efficiency welding power supplies, which not only have higher power output and lower energy consumption but also have longer service life. The application of this high-efficiency power supply not only improves welding efficiency but also reduces production costs, providing significant economic benefits.

III. Multi-Functional Welding Adaptability - Meeting Diverse Welding Needs

1)Various Welding Modes

To adapt to different welding requirements, the latest welding machines typically have multiple welding modes, such as manual arc welding (MMA/SMAW), gas-shielded welding (GMAW/GTAW), and resistance welding (RSW), among others. Megmeet Ehave2 CM multifunctional welding machine is a CO2/MAG/MIG/TIG/MMA/carbon arc gouging all-in-one welding machine model. Through simple switching, welders can freely choose between different welding modes, flexibly handling various welding tasks, greatly improving welding flexibility and adaptability.

2)Multi-Material Welding Capability

With the development of material science, the variety of welding materials is increasing. Megmeet welding machines have also significantly improved in material adaptability, able to handle various metal materials including steel, aluminum, titanium, stainless steel, and more. Some high-end models can also weld composite materials and high-temperature alloys, meeting the diversified needs of modern manufacturing.

3)Environmental Adaptability

Welding environments are usually complex and changeable, and Megmeet Intelligent Welding Machines have excellent environmental adaptability. Whether in high-temperature and high-humidity factory workshops or cold and dry outdoor construction sites, these welding machines can operate stably to ensure welding quality. In addition, some high-end welding machine models also have special functions such as dustproof, waterproof, and shockproof, further improving reliability in harsh environments.

IV. Safety Measures - Safety Guardians during Welding Processes

1)Intelligent Safety Protection

Safety is paramount during the welding process. Megmeet welding machines are equipped with intelligent safety protection systems that can monitor parameters such as current, voltage, and temperature in real-time during welding. Once abnormalities are detected, the system will automatically stop working and issue an alarm, effectively reducing welding accidents.

2)Protective Equipment

Megmeet welding machines are also equipped with various safety protection devices, such as automatic power-off devices, overload protection devices, protective masks, and more. These protective devices not only protect the safety of welders but also extend the service life of welding machines, enhancing overall safety and reliability.

3)Safety Operation Guidelines

To ensure operational safety, Megmeet Intelligent Welding Machines come with detailed safety operation guidelines and training videos, helping welders master the correct operating methods and safety precautions. Megmeet also provides professional safety training courses to enhance welders' safety awareness and operational skills, ensuring the welding process is safe and reliable.

V. Environmental Protection and Energy Efficiency - Vanguard of Green Manufacturing

1)Low Energy Consumption Design

Environmental protection and energy efficiency are important directions for modern industrial development, and Megmeet Intelligent Welding Machines have made positive efforts in this regard. Low energy consumption design not only reduces the operating costs of welding machines but also reduces energy consumption and carbon emissions, conforming to the concept of green manufacturing.

2)High-Efficiency Materials

In material selection, Megmeet welding machines widely use high-efficiency materials such as high-temperature and corrosion-resistant alloy materials. These materials not only improve the durability of welding machines but also reduce resource waste. Some welding machines even use renewable materials, further enhancing environmental performance.

3)Application of Environmental Protection Technology

Megmeet welding machines apply various environmental protection technologies, such as low smoke and dust welding technology, lead-free welding technology, etc. These technologies not only protect the health of welders but also reduce environmental pollution during the welding process, contributing to the realization of green manufacturing. The application of environmental protection technology establishes Megmeet welding machines as a benchmark in the industry.

VI. Market Applications and Prospects of Megmeet Welding Machines

1)Innovation, Research and Development

Megmeet continuously invests significant resources in technological innovation and R&D, committed to creating more intelligent, efficient, and environmentally friendly welding equipment. Through cooperation with multiple research institutions and universities, Megmeet continuously breaks through the frontier fields of welding technology, leading the industry's development.

2)Multi-Industry Applications

Megmeet intelligent welding machines, with their excellent performance and multi-functional adaptability, are widely used in multiple industries such as automotive manufacturing, aerospace, construction engineering, shipbuilding, etc. In these fields, Magmit welding machines have gained the trust and praise of numerous customers due to their high efficiency and high precision.

3)Market Prospects

With the continuous advancement of industrial intelligence and green manufacturing, the market prospects for Megmeet intelligent welding machines are broad. Their advantages in intelligent operation, high-efficiency performance, multi-functional adaptability, safety measures, and environmental protection, and energy-saving performance will continue to drive the development and progress of the welding industry.

VII. Conclusion:

In summary, new welding machines such as Megmeet intelligent welding machines demonstrate significant advantages in intelligent operation, high-efficiency performance, multi-functional adaptability, safety measures, environmental protection, and energy-saving performance. These unique performance characteristics not only improve welding quality and efficiency but also bring new opportunities and challenges to the development of the welding industry. In the future, Megmeet's intelligent welding machines will continue to innovate, bringing infinite possibilities to the future of welding technology.

Related articles:

1. Megmeet Full-Digital High-Frequency Inverter Welding Machine

2. Inverter vs. Transformer Welding Machines: Pros, Cons & Contrast

3. Powerful Heavy Duty Inverter Welding Machines For Precision Welding

4. Inverter Welder Problems and How to Solve Them?

5. How to Weld Aluminum with Inverter-Based Power Supplies?