Pulse welding is a simple idea with powerful results: instead of running a steady welding current, the power source alternates rapidly between a high (peak) current and a low (background) current. That on-off rhythm gives you much better control over heat input, weld puddle behavior and droplet transfer — which means cleaner beads, less spatter, reduced distortion and an easier time welding thin or difficult materials.

Table of contents:

1. What Is Pulse Welding, And How Does It Work?

1.1 Pulse Frequency

1.2 Peak Current / Background Current

1.3 Pulse Percentage (duty cycle)

2. Pulsed TIG Welding

2.1 Advantages of Pulsed TIG welding

2.2 Disadvantages of Pulse Welding

3. Pulsed MIG Welding

3.1 Pulse-on-pulse (double pulse) welding

3.2 Advantages of Pulsed MIG welding

3.3 Disadvantages of Pulse Welding

4. When to Use Pulsed TIG or Pulsed MIG

5. Practical setup tips and common settings

Conclusion

🧐 Pulsed Welding — FAQ

I. What Is Pulse Welding, And How Does It Work?

Pulse welding (used in both GTAW/TIG and GMAW/MIG contexts) controls the arc by switching the welding current between a peak and a background level at a set frequency. During the peak the arc melts metal and (in GMAW) pinches off a droplet; during the background the arc energy is reduced so the weld cools slightly and the puddle firms up. That controlled energy cycling limits overall heat input while still achieving good fusion when needed.

The technique becomes especially helpful on thin sections, highly conductive metals, out-of-position joints, or whenever you want a neat, narrow bead with minimal distortion and spatter.

1. Pulse Frequency:

Pulse frequency is how many peak–background cycles occur per second (measured in Hz). Practical ranges used in shop practice vary:

Very low frequencies (≈0.5–1 Hz): produce distinct, spaced “dabs” in the weld puddle — useful for the stacked-dimes look and precise manual control.

Mid-range (2–30 Hz): broad puddle control and aesthetic bead shaping.

High frequencies (≈100 Hz and upward): give a stiffer arc, narrower bead, deeper penetration and smoother metal transfer; industrial systems may go significantly higher for specialized processes.

The frequency choice strongly affects puddle behavior, travel speed and visual comfort — very high frequencies can create a strobe effect that some welders find disorienting.

2. Peak Current / Background Current:

Peak current (Ip) — the high amperage delivered during the pulse crest. This is what melts and, in GMAW, detaches the droplet.

Background current (Ib) — a reduced level that maintains the arc and prevents the weld pool from cooling completely. Background is often expressed as a percentage of peak (for example, Ib = 40% of Ip).

Adjusting peak vs. background lets you dial in penetration and heat input: more time or higher amplitude at peak = deeper penetration; higher background (closer to peak) = a hotter overall cycle and broader bead.

3. Pulse Percentage (Duty Cycle):

Pulse percentage (sometimes called the duty of the pulse) is the fraction of each pulse period spent at peak current. A 50% pulse percentage means equal time at peak and background.

Changing that percentage alters the arc’s effective heat:

Higher percentage → more time at peak → greater heat input and penetration.

Lower percentage → more time at background → lower heat input, narrower HAZ (heat-affected zone).

Typical ranges are often from about 20% up to 90%, depending on the material and application; beginners often start in the 40–60% range and tune from there.

II. Pulsed TIG Welding

Pulsed TIG (pulsed GTAW) applies the pulse concept to TIG’s non-consumable electrode process. The welder gets precise control of puddle size and heat without sacrificing the TIG arc’s inherent cleanliness and low spatter.

1. Advantages of Pulsed TIG welding:

Tighter heat control — better for thin materials (aluminum, stainless) and for small, precise joints.

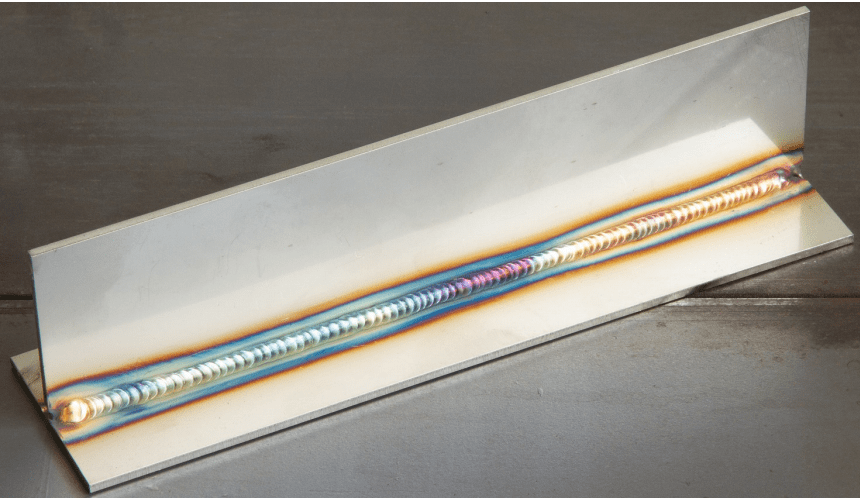

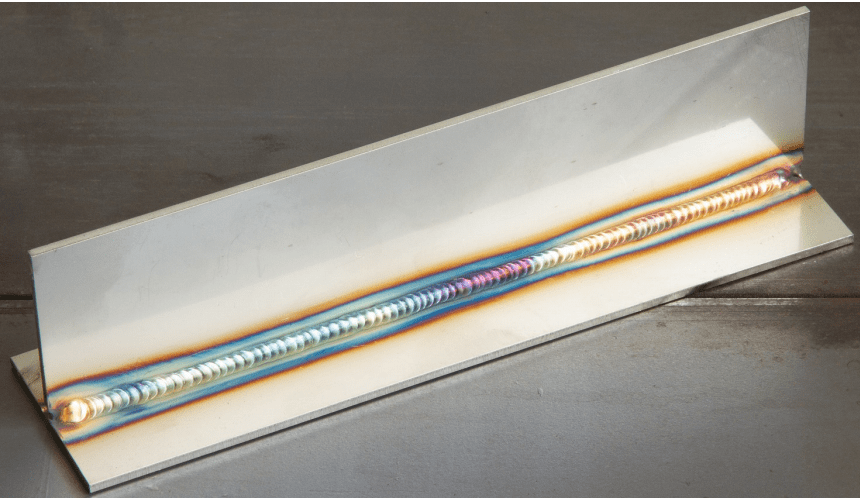

Improved bead appearance — easier to produce uniform, “stacked-dimes” style beads.

Reduced distortion and burn-through — the background time gives the joint cooling intervals.

Better control for out-of-position work — the puddle is firmer between peaks so gravity-sensitive joints are easier.

Easier dissimilar-metal welding — controlled heat reduces the likelihood of excessive intermetallic formation in some combinations.

2. Disadvantages of Pulse TIG Welding:

Complex setup: Multiple parameters — frequency, peak current, background current, and pulse percentage — must be tuned correctly. Poor settings can cause unstable arcs or uneven beads.

Slower travel speed: Because current repeatedly drops to background levels, heat input and deposition rates are lower, reducing productivity on thick materials.

Higher equipment cost: Machines with pulse control are more advanced and costlier than standard TIG welders.

Greater skill required: Welders must synchronize filler addition with the pulse rhythm, which takes practice.

Limited benefit on thick or mild steel: The process mainly helps with thin or heat-sensitive metals; for heavy sections, conventional TIG or MIG is often faster.

III. Pulsed MIG Welding

Pulsed MIG (pulsed GMAW) is a modified spray transfer. Instead of a continuous spray stream or short-circuit transfer, the power source produces a high-current peak to pinch and propel a single droplet, then reduces to background current to let the puddle stabilize. That gives controlled droplet transfer without contact between wire and puddle (non-contact transfer).

1. Pulse-on-pulse (double pulse) welding:

Some systems add a second, slower modulation on top of the main pulse (often called pulse-on-pulse, double pulse, or tandem pulse). The result is a layered effect — one waveform governs droplet formation, while a slower envelope shapes bead appearance and cooling cycles. This technique helps when you want excellent bead appearance on thin alloys while still maintaining high deposition control.

2. Advantages Of Pulsed MIG Welding:

Low spatter, cleaner welds — controlled droplet detachment reduces smoke and rework.

Better thin-metal performance — lower average heat reduces burn-through on thin aluminum and stainless.

Consistent metal transfer in challenging positions — pulsed spray is more forgiving in out-of-position welding than standard spray transfer.

Higher travel speeds with good control — when tuned properly you can increase deposition while keeping bead quality.

3. Disadvantages of Pulse Welding (MIG):

Complexity and cost — pulsed GMAW requires electronic control that can be costlier than simple CV machines.

Parameter sensitivity — shielding gas, wire chemistry, contact tip and nozzle setup are all more influential; poor gas control can defeat pulsed transfer.

Not universally superior — for some thick-section, high-deposition work conventional spray with higher continuous currents may be more efficient.

IV. When to Use Pulsed TIG Welding or Pulsed MIG Welding

Pulse welding is a tool — not a universal solution. Use it when the job benefits from tighter heat control, better bead appearance, or controlled droplet transfer:

Thin sections and foils: aluminum and thin stainless steel where burn-through and distortion are major concerns.

Out-of-position welding: background current stabilizes the puddle and reduces sagging.

Aesthetic or root passes: when bead appearance or minimal cleanup is important.

Dissimilar metals or high-conductivity alloys: pulse control reduces excessive heat flow and helps avoid defects.

High-frequency or automated applications: where waveform control and repeatability are critical (robotic welding lines, specialized manufacturing). High-frequency pulsed arcs are an active area of research and industrial application.

If your goal is maximum deposition on very thick sections or you lack the equipment/skill to tune the parameters, conventional continuous modes may still be preferable.

V. Practical setup tips and common settings

Start conservative. For TIG begin around 40–60% pulse percentage and a mid frequency (20–100 Hz) and adjust. For MIG, follow wire-manufacturer guidance for pulse settings and gas blends.

Use the right shielding gas. Pulsed spray transfer often requires specific gas mixes (for example, certain argon/oxygen or argon/helium blends) — wrong gas reduces stability.

Watch travel speed. Pulsed arcs are sensitive to travel speed; too slow = excess build, too fast = lack of fusion. Coordinate travel, filler feed (for TIG) and pulse rhythm.

Record workable recipes. Once you find a good pulse recipe for a joint and material, save it — the parameter set is often repeatable and worth documenting for production work.

Pay attention to contact tips and nozzle cleanliness (MIG): contamination or worn tips change waveform behavior.

Conclusion

Pulse welding is a versatile, modern way to take control of heat input, droplet transfer and bead appearance. When used with the right materials, gas, and technique it reduces distortion, cuts rework and produces attractive, consistent welds. It adds setup complexity and demands some tuning, but for thin-section work, out-of-position joints, aesthetic requirements, or automated processes it’s often the better choice.

🧐 Pulsed Welding — FAQ

Q1: Is pulse welding the same for TIG and MIG?

A: The basic idea (high/low current cycles) is the same, but application differs. Pulsed TIG controls puddle and heat for a non-consumable electrode; pulsed MIG controls droplet transfer and is a form of modified spray transfer.

Q2: Will pulsed welding reduce spatter?

A: Yes — especially in pulsed MIG, because each droplet is pinched and transferred cleanly during the peak portion, which reduces spatter compared to spray or short-circuit modes.

Q3: What frequency should I use?

A: There’s no universal number — try low frequencies (≈0.5–5 Hz) for distinct dabbing and visual effects, moderate (5–50 Hz) for general control, and higher (≈100 Hz+) for narrow, controlled arcs. Industrial systems can use even higher frequencies for specialized outcomes.

Q4: Can pulse welding be automated (robotic)?

A: Absolutely — the repeatability of waveforms makes pulsed welding popular for robotic and automated production where consistent heat input and bead geometry matter.

Q5: Any drawbacks to remember?

A: More setup variables to manage, higher equipment cost for advanced pulsing functions, and a learning curve for technique. For some heavy-section, high-deposition tasks conventional constant modes may be simpler and faster.

Related articles:

1. Pulse Function of Welders & Pros and Cons of Pulse Welding

2. Pulsed Welding Technology: Solution to Sheet Metal Burn-Through

3. Pulse Technology’s Role in Enhancing Efficiency and Precision

4. Should I TIG with or without pulse?

5. Pulse TIG welding: Process, Automation and Control